IMDS Services by Licentiesoft

Welcome to Licentiesoft, your trusted partner in achieving seamless compliance with the International Material Data System (IMDS) and Collaborative Data eXchange (CDX). Our comprehensive services are designed to empower manufacturers, ensuring adherence to industry standards and regulatory requirements. Let’s explore how Licentiesoft can guide you through the intricacies of IMDS and CDX compliance.

IMDS Services by Licentiesoft

At Licentiesoft, we offer a suite of IMDS services tailored to your needs:

Data Entry and Management: Efficiently input and manage material data with our expert support. Includes, IMDS Creation, Supplier Contact,Supplier IMDS Evaulation, BOM Analysis, etc

Regulatory Compliance: Ensure compliance with global environmental regulations through meticulous data reporting. Following Guide Lines like ELV, SVHC, GADSL ,following OEM guideline, Chemical Substances analysis for EU-REACH, SCIP, CMRT, PROP 65,POPs,BPR, etc

Lifecycle Integration: Seamlessly integrate IMDS into your product development lifecycle for enhanced efficiency.

Navigating with CDX Solutions

Collaborative Data eXchange (CDX)

CDX is a powerful platform complementing IMDS, facilitating collaborative data exchange between suppliers and manufacturers. Our CDX solutions provide:

Real-time Collaboration: Collaborate seamlessly with stakeholders, reducing lead times in data submissions.

Automated Validation: Minimize errors with automated validation checks, ensuring accurate and compliant submissions.

Streamlined Approval Processes: Expedite the approval process, reducing delays in regulatory submissions.

How Licentiesoft Enhances Compliance

Tailored Solutions for Manufacturers

Expert Guidance: Leverage the expertise of our professionals well-versed in global regulatory landscapes.

Cutting-edge Technology: Stay ahead with technology-driven solutions, ensuring a competitive edge in compliance management.

Proactive Updates: Stay informed about regulatory changes with our proactive communication and timely notifications

Request Quote

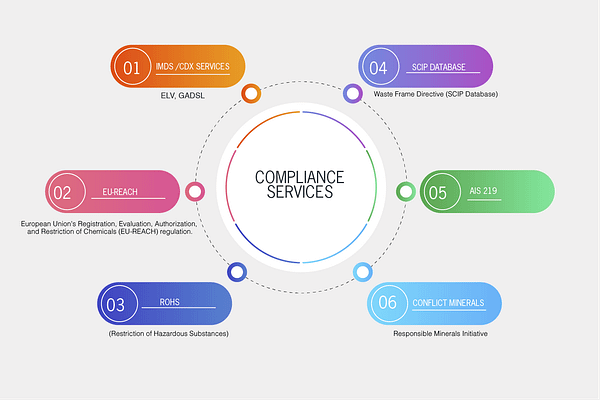

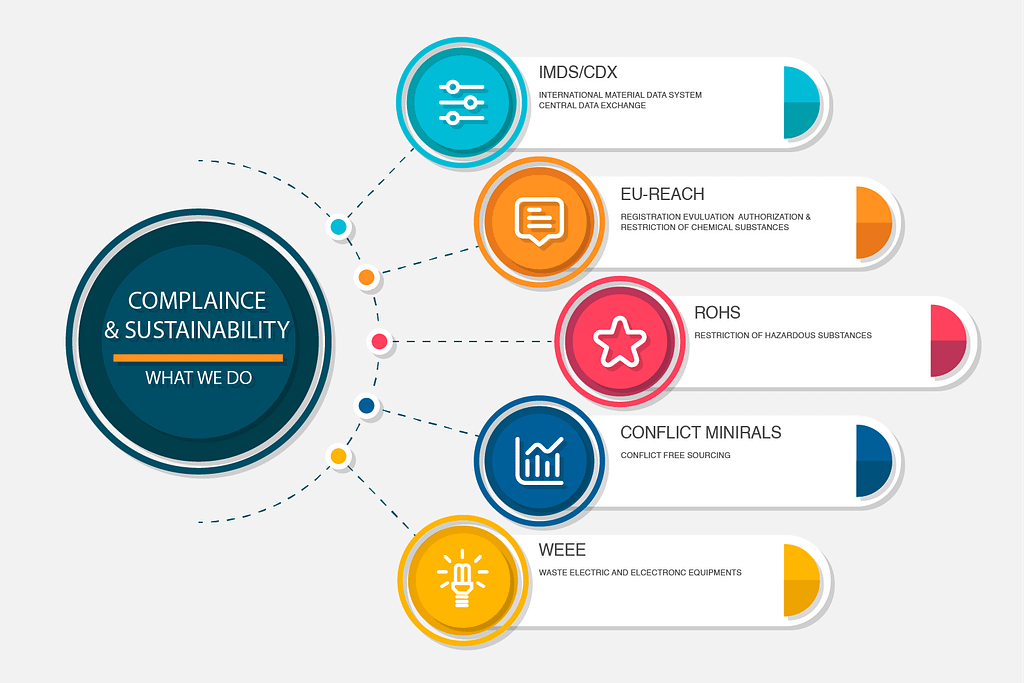

Our Complainces services

- IMDS (International Material Data System)

CDX (Central Data Exchange)

REACH (Registration, Evaluation, Authorization & Restriction of Chemical Substances)

- RoHS (Restriction of Hazardous Substances):

- Conflict Minerals (Responsible Minerals Initiative – RMI, formerly Conflict Free Sourcing Initiative – CFSI):

- Waste Management (European Regulations):

- WEEE (Waste Electrical and Electronic Equipment):

- ELV (End of Life Vehicle):

- Battery Directives:

- Prop 65 (California Proposition 65):

- Montreal Protocol:

- China, Korea, Japan (ELV):

- Taiwan, Korea, Japan (REACH):

- AIS -219

.

What is IMDS?

IMDS stands for the International Material Data System, a centralized database used in the automotive and related industries to manage and exchange information about materials in products.

Why is IMDS important?

IMDS is crucial for compliance with environmental regulations. It ensures that materials used in manufacturing adhere to global standards, promoting sustainability and regulatory adherence.

Who uses IMDS?

Manufacturers, suppliers, and organizations in the automotive supply chain use IMDS to input and exchange material data, ensuring compliance with various regulations

How does IMDS contribute to sustainability?

: By tracking and managing material data, IMDS helps organizations make environmentally conscious decisions, reducing the environmental impact of their products.

Is IMDS mandatory?

Yes, for many companies in the automotive industry, using IMDS is mandatory to comply with regulations and demonstrate the environmental impact of their products.

What is the process of submitting data to IMDS?

Companies submit data to IMDS by creating material data sheets, entering detailed information about the materials used in their products, and ensuring compliance with regulations.

Can IMDS data be shared across the supply chain?

Yes, IMDS facilitates the exchange of material data across the automotive supply chain, fostering collaboration and ensuring transparency in the use of materials.

How does IMDS support regulatory compliance?

IMDS helps organizations comply with various environmental regulations by providing a standardized platform to report and manage material data, ensuring adherence to global standards.

Is IMDS continuously updated?

Yes, IMDS is regularly updated to incorporate changes in regulations and industry standards, ensuring that the data remains current and relevant.

POPULAR NEWS

Latest From our blog

- February 4 2024

- fusioneventz

Mastering IMDS: IMDS Training Programs for Manufacturers

IMDS Training Programs In the rapidly evolving landscape of manufacturing, mastering International Material Data System (IMDS) compliance is not just a legal necessity; it’s a strategic imperative. Manufacturers need to navigate through IMDS compliance regulations, IMDS reporting guidelines, audits, legal aspects, and the certification process to ensure their products meet global environmental standards. One effective […]

Read More- February 4 2024

- fusioneventz

Mastering IMDS Reporting: A Step-by-Step Guide

Mastering IMDS Reporting: A Step-by-Step Guide IMDS Compliance Regulations Understanding the regulatory landscape is crucial for manufacturers aiming to achieve and maintain IMDS compliance. The IMDS Compliance Regulations encompass a set of guidelines and standards that govern the declaration and management of material data in products. Manufacturers must stay informed about specific regulations such as […]

Read More- January 25 2024

- fusioneventz

Navigating IMDS Compliance: A Guide for Manufacturers

Navigating IMDS Compliance involves a series of steps, each crucial to maintaining a seamless and compliant manufacturing process.

Read More